Metal fabrication is an essential process in industries ranging from automotive to construction. One critical step is shearing, which ensures clean and precise cuts for further use. Proper metal cutting can significantly influence the final product’s quality, the fabrication process’s efficiency, and the overall cost-effectiveness.

This comprehensive guide will explore the importance of proper metal cutting, the techniques involved, and how to ensure your metal is cut accurately for subsequent fabrication.

What is Metal Shearing?

Shearing, also known as metal cutting, is a cutting technique that passes through metal plates or sheets without burning or creating chips in the material. This technique works especially well when producing things with geometric shapes or straight edges. Metal cutting is crucial when preparing materials for additional manufacturing procedures like bending, welding, or assembly.

Why Proper Shearing is Crucial

Quality of the Final Product

The quality of the finished product can be greatly impacted by the shear’s accuracy and cleanliness. Inadequate shearing of the edges can result in welding or assembly process flaws. Accurate, clean cuts guarantee a better-quality product and minimize the need for further rework.

Efficiency in Fabrication

Careful metal cutting can streamline the fabrication process. Precise cutting results in improved assembly, which shortens the time and effort needed in later phases. This efficiency results in lower labor costs and quicker manufacturing times.

Cost-Effectiveness

One major advantage of correct metal cutting or shearing is waste reduction. Precise cutting reduces material waste, which can be a significant expense in industrial production. Rework and defect reduction also save time and resources, which improves cost-effectiveness even more.

Techniques for Proper Shearing of metal

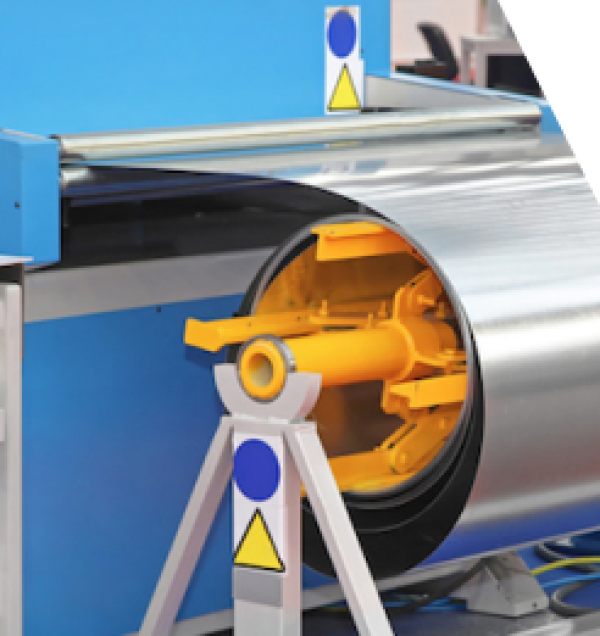

Choosing the Right Equipment

The first step in ensuring correct metal cutting is to choose the right shearing equipment. Pneumatic, hydraulic, and mechanical shears are suitable for varying thicknesses and materials, and each has advantages. Purchasing top-notch shearing equipment can greatly impact the precision and consistency of cuts.

Maintaining Sharp Blades

To get clean cuts, the shearing blades must be extremely sharp. Rough edges, burrs, and even material deformation can result from dull blades. Optimal cutting performance requires timely blade replacement and routine maintenance.

Proper Material Handling

How the metal is treated during the shearing process can affect the quality of the cut. Making sure the material is firmly fastened and positioned can achieve greater accuracy in cutting. Furthermore, utilizing supports and guides can help preserve the metal’s stability during shearing.

Adjusting Shearing Parameters

The shearing process can be optimized for varying materials and thicknesses by adjusting factors such as blade clearance, cutting angle, and shear speed. By adjusting these settings, you can guarantee smooth cuts and avoid problems like edge deformation.

Best Practices for Metal Fabrication

Pre-Shearing Inspection

Before shearing, inspect the metal for defects or imperfections affecting the cut quality. Removing contaminants, such as oils or rust, can also improve the shearing process’s effectiveness.

Post-Shearing Finishing

Certain edges could need further polishing after shearing to get rid of burrs or sharp edges. Deburring tools and edge sanders can be used to create a smooth finish and make the pieces safe to handle and prepared for additional manufacturing.

Regular Training and Skill Development

The success of the operation can be greatly impacted by ensuring that personnel are properly trained in the use of shearing equipment and are aware of its material qualities. Operators can remain current on the newest methods and best practices by participating in regular training and skill development programs.

Shearing is the initial step of metal fabrication

Accurate metal cutting is an essential first stage in metal manufacturing. By making sure that the cuts are clean and exact, you may save costs, increase fabrication efficiency, and improve the quality of the finished product. Investing in the proper tools, keeping your blades sharp, and adhering to best practices can greatly impact your metal fabrication operations.

Learn more about metal shearing from Cresco

Looking for a guide to shear your metal sheets? Call us at – 714 525 2326 or visit our website to check out our exclusive services.