A Glossary of Terms Related to Robotic Welding Every Manufacturer Should Know

Robotic welding is at the forefront of automation in the rapidly changing field of metal manufacturing. Manufacturers of robotic systems must be familiar with the essential terminologies to discuss, implement, and optimize their welding processes properly. This blog of robotic welding phrases will help both professionals and those unfamiliar with automated welding technology gain a fundamental grasp of these phrases.

- Robotic Arc Welding

Robotic arc welding is the automation of the arc welding process, which involves melting metal at the welding spot with an electric arc using a robotic arm. It is the most used type of robotic welding in sectors like the production of heavy machinery and automobiles.

- Torch

The torch of the robotic welder is in charge of providing the weld with the wire electrode, shielding gas, and welding current. Precision and stability are essential for reliable outcomes, and these attributes are built into robotic welding torches.

- Weld Path

The welding torch’s route is referred to as the weld path. This path is configured to provide homogeneous welds with little variance in robotic welding, guaranteeing high accuracy.

- Robot Controller

The robotic welding system’s brain is called a robot controller. It controls the robotic arm’s motion, turns on the torch, and communicates with other parts, including sensors and safety systems.

- End Effector

The part at the end of a robotic arm in a robotic welding system is called the end effector, usually a welding torch or similar material handling instrument. This component is essential to welding for precise guidance of the welding torch and carry out auxiliary duties like material management.

- Arc Welding Power Supply

The power supply supplies the electric current required to form an arc between the electrode and the base material. This power supply can be adjusted depending on the type of weld and the material being welded.

- Arc Length

The distance during welding between the welding electrode and the base material is known as the arc length. Maintaining a constant arc length during robotic welding is essential to creating high-quality welds with few flaws.

- Shielding Gas

Shielding gas, such as argon, helium, or carbon dioxide, is utilized in many robotic welding procedures to shelter the molten weld pool from atmospheric pollution, guaranteeing strong and clean welds.

- Weld Pool

The little area of molten metal formed during the welding process is called the weld pool. Its dimensions and shape are essential for the weld to be strong and look good. Robotic technologies carefully regulate the welding process’s speed and heat input to produce the best weld pool.

- Weld Bead

As the weld pool hardens, a visible line of metal called a weld bead forms. Robotic welding guarantees uniform bead size, shape, and smoothness, essential for the weld’s structural integrity and aesthetic appeal.

- Weld Penetration

The depth to which the weld pool penetrates the base material is called weld penetration. A proper penetration guarantees a strong weld connecting the materials. Robotic systems frequently use sensors to guarantee uniform penetration throughout the welding process.

- Robot Work Envelope

The area the robotic arm can reach and operate inside is known as the work envelope. Manufacturers must thoroughly understand the work envelope to place robots in workspaces properly.

- Positioner

A positioner is an instrument used in welding that holds and moves the workpiece. Positioners aid in the optimal orientation of components for welding in robotic welding, guaranteeing consistency and minimizing the need for manual intervention.

- TIG (Tungsten Inert Gas) Welding

Robotic welding systems frequently employ TIG welding, a high-precision welding technique. It works with non-consumable tungsten electrodes and is commonly employed for applications demanding high-quality welds on thinner materials.

- MIG (Metal Inert Gas) Welding

One of the most used automated welding techniques is MIG welding. It is renowned for its speed and effectiveness when welding thicker materials and employs a consumable wire electrode.

- Adaptive Welding

Adaptive welding systems are robotic welding systems that automatically modify their parameters (like feed rate, voltage, or speed) in response to real-time sensor data. These systems are designed to handle changes in the welding environment or materials.

- Seam Tracking

Robotic welding systems use seam tracking technology to follow the weld seam automatically. It guarantees that the torch remains in line with the joint even when the workpiece is not positioned precisely or the joint path slightly shifts.

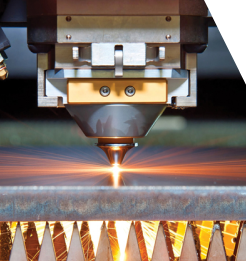

- Laser Welding

Concentrated laser beams are used in laser welding to melt and fuse materials. Because of its great precision, robotic systems frequently use it for delicate welding tasks or when extremely fast welding speeds are necessary.

- Fume Extraction

The term “fume extraction” describes eliminating toxic gases produced during welding. Fume extraction systems are frequently included into robotic welding stations to ensure a secure working environment.

- Plasma Arc Welding

Robotic TIG welding is comparable to plasma arc welding. However, plasma arc welding uses a stronger arc. Aerospace and other high-precision sectors frequently employ it.

Frequently Asked Questions (FAQs)

- What is the role of shielding gas in robotic welding?

Shielding gas ensures stronger and cleaner welds by shielding the molten weld pool from atmospheric contaminants. Gases utilized in various welding processes include carbon dioxide, argon, and helium.

- How does seam tracking improve robotic welding?

Thanks to seam tracking, robotic welders can automatically follow the weld seam, correcting for minute differences in the workpiece or joint.

- What is the difference between Metal Inert Gas (MIG) and Tungsten Inert Gas (TIG) welding in robotic systems?

TIG welding employs a non-consumable tungsten electrode for high-precision welding on thinner materials. In contrast, Metal Inert Gas (MIG) welding uses a consumable wire electrode and is faster, making it appropriate for larger materials.

- Can robotic welding be used for custom, low-volume jobs?

Indeed, robotic systems can be effectively reconfigured, making them viable even for custom, low-volume production, thanks to developments in offline programming and adaptive welding technology.