Mastering Welding Technique – a Deep Dive Into Innovative MIG Welding Techniques

The world of metal fabrication is fast-evolving, and staying at the top of the curve needs more than basic skills. It demands innovation, mastery, and adaptability instead of surface-level knowledge. One of the most broadly used welding methods is Metal Inert Gas (MIG), popular for its precision, speed, and ease of use. Whether you are new to the welding domain or an experienced professional interested in refining your technique, knowing the latest MIG welding innovation is necessary. It can remarkably elevate your craftsmanship.

At Cresco, the expert team provides top-tier on-site welding services and advanced manufacturing solutions. This blog will discuss cutting-edge MIG welding techniques, practical and valuable welding tips for beginners, and how professional MIG welding can help assure structural integrity and optimal results for your projects.

What is MIG welding?

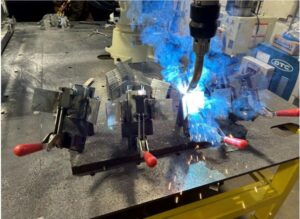

MIG welding is also interchangeably used for Gas Metal Arc Welding (GMAW), a technique where a consistent wire electrode is fed through the welding gun and into the weld pool, mixing the base materials together. A shielding gas is used to protect the weld from contaminants in the air, which also ensures high-quality and clean joints.

This technique is specifically familiar as it is relatively easy to learn, versatile across materials (such as stainless steel, steel, and aluminum), and creates cleaner welds with less spatter than other welding techniques.

Why mastering MIG welding matters?

Even though MIG welding is known as beginner-friendly, mastering it requires an understanding of equipment, innovation, and technique. A professional MIG weld looks clean and assures safety and durability, which is important in industries such as automotive, aerospace, manufacturing, and construction.

MIG welding services from Cresco are designed to meet industrial-grade standards, assuring clients receive the most reliable and structurally sound welds possible, either in the workshop or through on-site welding services.

Innovative MIG welding techniques to elevate your skills

- Pulse MIG welding

Pulse MIG welding is a technique in which the welding machine alternates between low and high current. This pulsing effect manages heat input and reduces distortion, which is particularly useful when working with thinner materials.

Advantages:

- Better control over heat-affected zones

- Minimized spatter and clean-up time

- Enhanced weld appearance and integrity

At Cresco, we believe in incorporating pulse MIG into on-site welding services for accurate control and exclusive finishes on highly demanding projects.

- Spray transfer technique

This technique involves spraying fine droplets of molten metal throughout the arc into the weld pool. Although it requires higher amperage and voltage, it delivers a smooth, high-penetration weld, perfect for thicker metals.

When to use it:

- Welding thick steel components

- Projects that need deeper penetration and smooth welds

- Indoor welding environment (as it includes gas shielding)

Spray transfer is a preferred method in Cresco’s MIG welding services for high-strength applications and heavy-duty structural jobs.

- Short-circuit transfer

This method is perfect for comparatively thin metals and out-of-position welding. It allows an electrode to touch the workpiece and make a short circuit, making it perfect for low-heat and intricate jobs.

Best applicable for:

- Automotive parts

- Sheet metal work

- Tight tolerances and complex geometries

- Dual shield MIG welding

Dual shield MIG welding is a hybrid approach that offers exclusive penetration and less spatter, even in windy outdoor situations. It also integrates solid and flux-cored wire with shielding gas.

Why is it innovative?

- Integrates the advantages of traditional MIG and flux-core

- Ideal for heavy and structural fabrication

- Allows for high deposition rates

Our on-site welding usually deploys dual shield methods in field settings, where situations are less controlled, but results should remain top-notch.

Beneficial welding tips for beginners

Mastering MIG welding begins with getting the basics correct. If you are a beginner in the world of welding, some essential tips are provided to help you develop a solid foundation.

- Understand your equipment

Learn how every part of your welding setup functions – from the wire feeder and welding gun to the shielding gas flow rate. The more educated you are with your tools, the easier it will be to adjust and troubleshoot settings during a weld.

- Master proper positioning

Your stance, angle of torch (usually 10-15 degrees), and travel speed remarkably affect weld quality. Practice controlling the steadiness of your hands and continuous movement along the joint.

- Clean the workpiece

Contaminants such as rust, paint, and oil can ruin the integrity of the weld. Always clean the metal surface properly before beginning the weld.

- Start with short welds.

Beginners usually benefit from making short weld beads, which allow for better control and help identify problems such as undercutting, porosity, or lack of fusion early on.

Frequently Asked Questions (FAQs)

Q1: What is the difference between MIG and TIG welding?

A: Continuously fed wire is used in MIG welding, which is typically quicker and simpler for novices. Contrarily, TIG welding needs greater precision and employs a non-consumable tungsten electrode, which makes it ideal for thin or complicated welds.

Q2: Is MIG welding good for outdoor use?

A: Because wind quickly impacts shielding gas, MIG welding is best utilized indoors. Nonetheless, flux-cored techniques or dual shield MIG welding can work well outside, particularly for Cresco’s on-site welding services.

Q3: How can I improve my MIG welding skills as a beginner?

A: Pay attention to the basics: clean your metal, keep your travel speed constant, and modify the wire speed and voltage according to the material. Over time, using these beginner-friendly welding suggestions will significantly improve your skills.

Q4: What industries commonly use MIG welding services?

A: Because of its speed and versatility, MIG welding is utilized in various industries, including heavy equipment production, automotive, construction, aerospace, and shipbuilding.