A Comprehensive Guide of Mastering CNC Turret Punch Basics

Introduction

Welcome to our comprehensive guide on CNC turret punch basics. In this article, we will explore the key features, functionalities, and applications of CNC turret punches. Whether you are new to the world of CNC machining or looking to enhance your understanding, this guide will provide you with valuable insights into this cutting-edge technology.

What is a CNC Turret Punch?

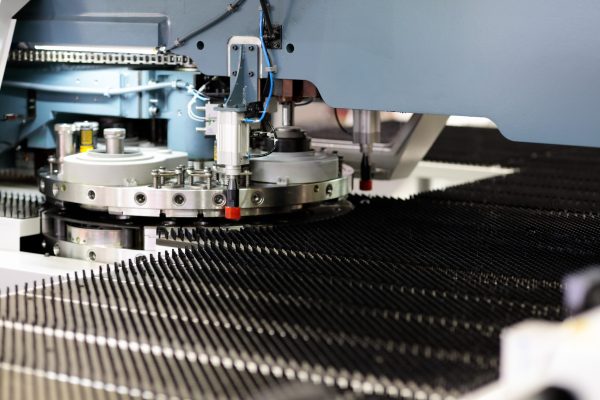

A CNC turret punch is a computer-controlled machine that uses a rotating turret to hold multiple tools. It utilizes a punching mechanism to create precise holes, shapes, and patterns in various materials, including metal sheets. The main feature of a CNC turret punch is its ability to quickly and accurately punch, form, and cut metal components.

Working Principle

CNC turret punches operate based on a set of programmed instructions. The machine’s computer numerical control (CNC) system coordinates the movement of the turret, positioning the appropriate tool in alignment with the material to be processed. The punching action is controlled by hydraulic or mechanical mechanisms, ensuring precise and consistent results.

Features and Benefits

3.1 Versatility and Flexibility

CNC turret punches offer a wide range of capabilities, making them highly versatile for various applications. They can perform tasks such as hole punching, forming, tapping, and engraving. With the ability to accommodate different tools, CNC turret punches provide flexibility in manufacturing processes.

3.2 High Precision and Accuracy

One of the key advantages of CNC turret punches is their exceptional precision and accuracy. The computer-controlled system ensures consistent results, minimizing errors and reducing material waste. This level of precision is crucial in industries where tight tolerances are required.

3.3 Efficiency and Productivity

CNC turret punches are known for their high-speed operation, enabling efficient production processes. The automatic tool changing feature eliminates the need for manual tool adjustments, reducing downtime and increasing productivity. With their ability to perform multiple operations in a single setup, CNC turret punches streamline manufacturing workflows.

3.4 Cost-Effective Manufacturing

By optimizing material usage and reducing scrap, CNC turret punches contribute to cost-effective manufacturing. The ability to automate repetitive tasks and produce complex shapes in a single operation saves time and labor costs. Additionally, the accuracy and consistency of CNC turret punches minimize rework and enhance overall production efficiency.

Applications

CNC turret punches find applications across various industries, including:

4.1 Sheet Metal Fabrication

In the sheet metal fabrication industry, CNC turret punches are widely used for cutting, perforating, and forming metal sheets. They can create precise holes, slots, and intricate patterns, enabling the production of complex sheet metal components.

4.2 Electrical Enclosures

CNC turret punches play a crucial role in manufacturing electrical enclosures. They can quickly and accurately punch holes for mounting components, cable entry points, and ventilation.

4.3 Automotive Industry

CNC turret punches are utilized in the automotive industry for producing parts such as brackets, panels, and mounting plates. They ensure the accuracy and consistency required for assembling various automotive components.

4.4 HVAC and Ventilation

In the HVAC and ventilation sector, CNC turret punches are used to create ductwork, grilles, and other components. The ability to accurately punch holes and shape metal sheets is essential for optimizing airflow and ensuring efficient system performance.

4.5 General Manufacturing

CNC turret punches find applications in various other manufacturing sectors, including furniture production, signage, appliance manufacturing, and more. Their versatility and precision make them indispensable for creating high-quality metal components.

Conclusion

CNC turret punches are revolutionizing the manufacturing industry with their versatility, precision, and efficiency. This guide has provided an overview of the basics, features, benefits, and applications of CNC turret punches. By harnessing the power of this advanced technology, businesses can enhance their productivity, reduce costs, and achieve superior manufacturing results.

For more information go to https://crescocustommetals.com/

https://goo.gl/maps/GSjzoEtWUzVi6F9P9

https://maps.google.com/maps?cid=7872978117429769224