The Benefits and Applications of Custom Aluminum Fabrication in Modern Manufacturing

Aluminum remains a topic of discussion for engineers, manufacturers and research persons for decades. Within the industrial landscape, custom aluminum fabrication plays an important role in revolutionizing the entire manufacturing procedure. It is a versatile material that caters to other important features, including durability and cost-effectiveness. This metal has become the preferred material for many business industries. From automotive to aerospace and electronics to construction, customized aluminum fabrication provides tailored solutions to meet particular industrial requirements. In this blog we will understand the main advantages as well as practical applications of aluminum fabrication in the modern manufacturing world.

Advantages of Custom Aluminum Fabrication

- Lightweight and high strength

One of the important reasons manufacturers prefer aluminum is the excellent strength-to-weight ratio. Aluminum is remarkably lighter than steel while maintaining considerable structural integrity. This feature makes it a perfect selection for industries that need lightweight yet strong materials, including automotive, transportation, and aerospace.

- Corrosion resistance

Aluminum naturally generates a protective oxide layer that prevents corrosion and rust. Contrary to steel, which needs consistent maintenance and coatings for oxidation prevention, aluminum withstands harsh environments with minimal upkeep. It makes the metal a perfect choice for applications in construction, outdoor and marine industries.

- Flexibility in design and fabrication

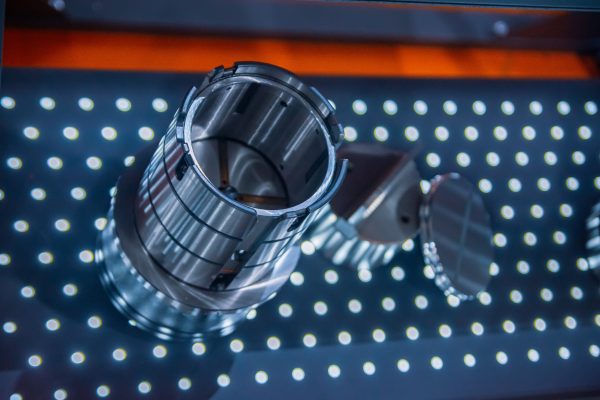

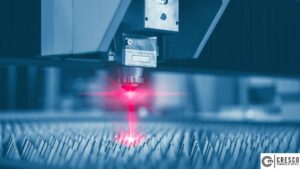

Metal fabrication companies can create intricate as well as highly specialized custom designs with aluminum fabrication. With technologies as CNC machining, extrusion and laser cutting, aluminum can be molded into intricate shapes with precision. This flexibility is significantly beneficial in industries that need detailed components for example medical and electronics equipment.

- Cost-effectiveness

In comparison to other metals, aluminum is a relatively easier to fabricate and an affordable option. Its machinability decreases production time and energy consumption, reducing manufacturing costs. Along with this, recyclability is a feature that makes aluminum more cost-effective and an eco-friendly choice for sustainable manufacturing.

- Thermal and electrical conductivity

Aluminum is considered as an excellent conductor of electricity and heat. It makes aluminum a preferred material in sectors including electrical engineering and HVAC (heating, air conditioning and ventilation) where effective heat dissipation is essential. Custom aluminum fabrication assures that heat exchangers, electrical components and cooling systems are designed for maximum efficiency.

- Eco-friendly and sustainable

Sustainability is an emerging concern for the manufacturing industry worldwide. Aluminum is 100% recyclable without compromising its properties, eliminating environmental impact and waste—companies prioritizing eco-conscious production benefit from utilizing aluminum as a sustainable material selection.

Applications of Custom Aluminum Fabrication in Different Industries

- Aerospace and automotive industry

The automotive and aerospace industry depends heavily on aluminum for its lightweight properties. Custom production technique allows for the fabrication of durable aircraft parts, structural reinforcements, car frames and engine components. The reduced weight enhances fuel efficiency and overall performance.

- Construction and architecture

Within the construction industry, aluminum is widely utilized for window frames, structural elements, roofing panels, and doors. Custom aluminum fabrication allows architects and engineers to create modern, aesthetically pleasing designs with increased durability and resistance to environmental factors.

- Electronics and electrical components

The electrical conductivity of aluminum makes it an essential material in the electronics industry. It is utilized in heat sinks, wiring solutions, and circuit boards to enhance longevity and performance. Custom fabrication assures that these parts meet precise specifications for effective functionality.

- Medical as well as healthcare equipment

The medical sector benefits from the non-toxic and corrosion-resistant properties of aluminum. Customized aluminum fabrication is utilized to make surgical instruments, imaging equipment components, medical device casings and hospital furniture assuring reliability and hygiene.

- Industrial machinery and equipment

Manufacturing plants need heavy-duty equipment and machinery to operate effectively. Custom fabrication allows the production of robotic arms, conveyor systems and machine parts that increase operational efficiency and productivity.

The Future of Custom Fabrication with Aluminum

With the advancements of technology, custom fabrication with aluminum is expected to become even more sophisticated. Innovations including AI-driven machining, 3D printing and automation will further enhance cost-savings, efficiency and precision. Along with this, the need for sustainable materials will continue to drive the adoption of aluminum in different industries.

FAQs About Custom Aluminum Fabrication

- What industries benefit the most from custom aluminum fabrication?

Custom aluminum fabrication is very advantageous to industries including aerospace, automotive, construction, electronics, medical, and industrial manufacture because of its adaptability, robustness, and affordability.

- How does aluminum compare to steel in terms of strength and weight?

Although aluminum is lighter than steel, it is nevertheless very strong. Aluminum’s greater strength-to-weight ratio makes it more appropriate for lightweight and high-performance applications, even if steel is stronger in some situations.

- Is aluminum environmentally friendly?

Indeed, aluminum is among the most environmentally friendly materials out there. It has a smaller environmental impact than other metals because it is 100% recyclable and requires less energy to process.

- What are the most common custom aluminum fabrication techniques?

CNC machining, laser cutting, welding, extrusion, and 3D printing are examples of common methods. These techniques enable producers to produce accurate, personalized aluminum parts for a range of uses.

Aluminum custom fabrication is still essential to contemporary production, providing solutions that boost productivity, sustainability, and product innovation. Aluminum is an essential material in today’s industrial world due to its special qualities, whether it is used in electronics, building, or aerospace.