Common Press Brake Bending Applications for Metals

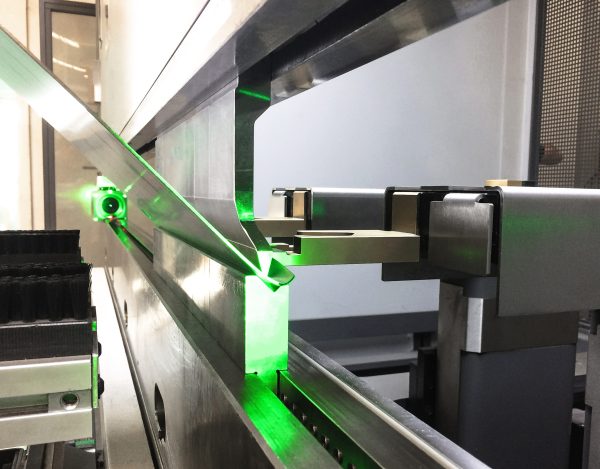

Brake press bending has its origins in centuries past. The archaic language used in the development of press brakes contributed to this machine’s unusual name. Middle English used the verb “to brake” to mean “to bend. The word “press” in the 14th century meant a device that applied a squeezing force. Therefore, a press brake was a mechanism for bending metal by squeezing it. Over time, technology created more powerful brake press machines that used hydraulic or electronic power to bend the metal. These more powerful tools allow for bending larger pieces of metal up to ½-inch thick and 12 feet long.

The process of brake press bending uses a variety of dies and tools to achieve different types of finished products. Quality metal bending appears as a frequently used process in several industries, which include the following:

Furniture

Large pieces of furniture formed from pieces of metal require press brake bending to create the parts. For example, large stainless steel countertops used in restaurant food preparation areas and modern home kitchens have the advantage of easy cleaning and resistance to rust and staining damage. To form the large pieces of stainless steel needed for these, a press brake machine is often required.

Automotive and Aerospace

Automotive and aerospace sectors have large metal panels that need the structural stability of being formed from single sheets of metal. Brake press bending can create these panels reliably. These machines can also create individual panels for automotive repairs done by body shops.

Metal Containers

Large metal containers may start from sheet metal and put through a press brake to bend it into shape for forming a container. The press brake operator needs to know the properties of the metal and how it will respond to bending to create the strongest part.

In fact, the expertise required of press brake operators is such that this is not a job for an inexperienced metal worker. Failure to account for differences in metal ductility can cause massive problems. To prevent such issues, at Cresco Commercial Metals, we only use knowledgeable, well-trained operators and pass all products through our quality assurance team to ensure the best results.

Let Cresco Commercial Metals Take Care of Your Metal Needs

If you have metal fabrication needs, let us at Cresco Commercial Metals handle them. We have a professional shop in Orange County that has more than 14 years of experience. Contact us to get your projects finished quickly and to our quality assurance team’s high standards.

Sources

https://steffweld.com/2021/02/17/7-products-that-could-come-from-a-press-brake/

https://www.thefabricator.com/thefabricator/article/bending/why-is-it-called-a-press-brake-

https://crescocustommetals.com/services/brake-press-services/

https://crescocustommetals.com/

https://crescocustommetals.com/contact-us/