California Industrial Trends in Stainless Steel Fabrication for 2024

An important material in California’s booming industrial environment is stainless steel. In industries ranging from healthcare to construction, stainless steel is essential due to its durability, resistance to corrosion, and adaptability. In 2024, the state is witnessing revolutionary developments and new trends that are altering the production and application of stainless steel.

This blog explores the current trends in stainless steel fabrication, the driving forces behind these changes, and the industries benefiting most from these innovations in California.

The Importance of Stainless Steel Fabrication in California

Stainless steel is indispensable in California’s diverse economy, supporting industries such as:

- Construction: High-rise buildings, bridges, and urban infrastructure.

- Energy: Renewable energy projects, pipelines, and power plants.

- Food Processing: Equipment that meets stringent hygiene standards.

- Medical: Surgical instruments and hospital-grade furniture.

- Technology: Precision components for electronics and robotics.

Fabrication of stainless steel is changing quickly to satisfy industry demands while abiding by stringent environmental rules as a result of California’s stress on sustainability, efficiency, and innovation.

Key Trends in Stainless Steel Fabrication in 2024

-

Automation and Smart Manufacturing

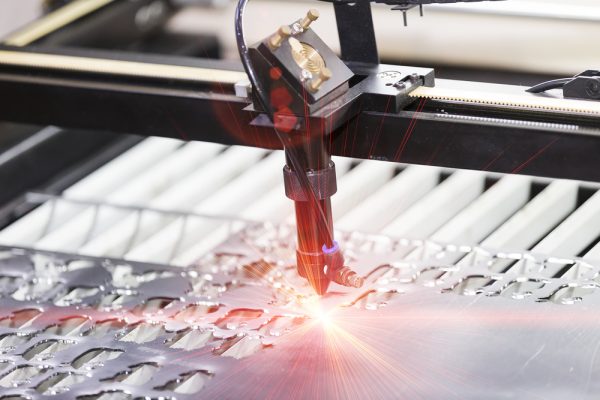

California’s tech-driven companies are infusing automation into fabrication processes. Robotic welders, sophisticated CNC machines, and AI-powered navigation systems increase output while reducing human error.

- Benefits: Precision in cutting, bending, and welding stainless steel components.

- Impact: quicker project completion and reliable quality for sectors with strong demand, such as automotive and aerospace.

-

Sustainable Fabrication Practices

Sustainability is a top priority in 2024, with fabricators adopting eco-friendly techniques:

- Low-Energy Welding: Using energy-efficient methods like laser or friction welding.

- Water Recycling Systems: Reducing water wastage during cutting and cooling.

- Recycling Stainless Steel Scraps: Maximizing material reuse to lower environmental impact.

California’s environmental policies, such as CARB restrictions, stimulate fabricators to innovate while reducing their carbon footprint.

-

Advanced Alloys for Specialized Applications

Industries demand stainless steel alloys tailored to specific needs. For example:

- Duplex Stainless Steel: Used in marine environments for enhanced corrosion resistance.

- High-Temperature Alloys: Designed for industrial ovens and heat exchangers.

- Bio-Compatible Alloys: Essential in medical and food-grade applications.

These specialty alloys support California’s standing as a technical leader by ensuring performance and durability under particular circumstances.

-

Growth of Modular Fabrication

As the metal is popular for its versatility and simplicity of assembly, modular stainless-steel components are becoming more useful. Sectors like energy and construction utilize modular solutions to reduce costs and expedite project schedules.

- Applications: Prefabricated piping systems, structural components, and modular kitchens.

- Advantage: Simplifies on-site installation while maintaining high-quality standards.

-

Additive Manufacturing (3D Printing)

Stainless steel 3D printing is a technique for custom metal fabrication. This technology can now create intricate geometries and lightweight designs that were previously impossible with conventional techniques.

- Use Cases: Custom components for aerospace, automotive, and medical industries.

- Benefits: Reduced material waste and quicker prototyping cycles.

California’s Leading Industries Driving Stainless Steel Fabrication

- Aerospace and Defense

Stain steel is important for defense and aerospace equipment because of its hardness and capability to withstand rough temperatures and conditions. Californian fabricators offer lightweight components and quality parts to this high-tech industry.

- Renewable Energy

California’s push towards renewable energy drives the requirement for stainless steel in solar panel frames, wind turbine parts, and hydrogen storage systems. Because of the metal’s resilience, these buildings can endure severe weather conditions.

- Construction and Architecture

Modern architecture supportss stainless steel because of its durability and visual attractiveness. California’s famous skylines are enhanced by the distinctive facade, railing, and structural element designs made by fabricators.

- Food and Beverage Industry

Stainless steel is essential for equipment used in the state’s flourishing food processing industry that complies with strict FDA and USDA regulations. Fabricated parts need to be hygienic and long-lasting, from conveyor systems to tanks.

Cresco’s Role in Shaping the Future of Stainless Steel Fabrication

Cresco is at the forefront of stainless steel fabrication, contributing to California’s industrial success with:

- Innovative Techniques: Leveraging automation, advanced alloys, and sustainable practices.

- Custom Solutions: Meeting the unique demands of clients across industries.

- Quality Assurance: Adhering to rigorous standards to deliver top-notch components.

- Sustainability Initiatives: Implementing eco-friendly processes that align with California’s green policies.

Because of its devotion to quality, Cresco is a reliable partner for businesses that depend on the manufacturing of stainless steel.

The Future of Stainless Steel Fabrication in California

The outlook for stainless steel fabrication in 2024 and beyond is bright, with advancements driven by:

- Digital Twins: Simulating fabrication processes to optimize designs and reduce waste.

- Collaborative Robotics (Cobots): Enhancing human efficiency in fabrication tasks.

- Increased Recycling Efforts: Ensuring a closed-loop system for stainless steel production.

By embracing innovation and sustainability, California’s stainless steel fabricators are poised to lead the global market.

FAQs on Stainless Steel Fabrication

- What makes stainless steel ideal for industrial applications?

Because stainless steel is strong, resistant to corrosion, and heat-tolerant, it may be used in demanding settings including the energy, medical, and construction sectors.

- How is sustainability addressed in stainless steel fabrication?

Contemporary methods’ main goals are adopting water-efficient processes, reducing energy consumption, and recycling scrap. Because stainless steel is 100% recyclable, it promotes environmentally conscious behaviour.

- What industries benefit the most from stainless steel fabrication in California?

The main industries influencing the state’s demand for stainless steel are construction, aerospace, renewable energy, food processing, and healthcare.

- How does Cresco stay ahead in the stainless steel fabrication industry?

To provide premium, tailored solutions for a range of industries, Cresco uses state-of-the-art technologies, invests in R&D, and prioritizes sustainability.

California is still the leader in stainless steel manufacturing, and 2024 will be a big year for development and innovation. Thanks to companies like Cresco, the sector is well-positioned to meet changing demands while promoting sustainable practices.