Welding or Fabrication – Which One Is Best Suited for Custom Metal Fabrication?

Considering the case of custom metal fabrication, industries or businesses usually debate whether to select welding or fabrication. Both techniques are an integral part of metalwork, they provide distinct functions and contribute differently for custom projects. Understanding the roles of fabrication and welding will help you to make an informed decision about the best fitted technique for your particular needs.

Understanding Metal Fabrication

Metal fabrication is a wider procedure encompassing bending, cutting and assembling metal structures for the final product. This procedure includes different techniques including forming, machining, and welding. Fabrication is usually used to make complex structures from raw materials, transforming plates, tubes, and sheets into usable parts. Custom metal fabrication allows unique, tailor-made solutions suitable for different industries, including industrial manufacturing, aerospace and automotive.

What is Welding?

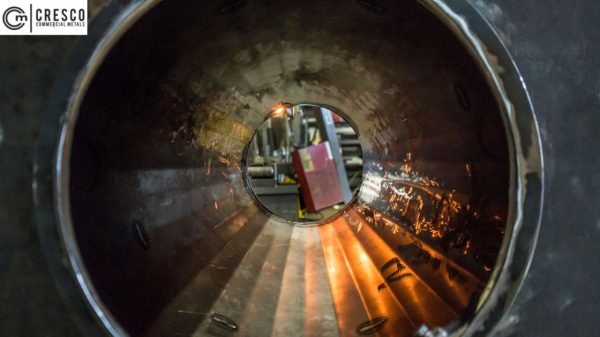

Welding is a unique technique within metal fabrication that joins two or more metal pieces by applying pressure and heat. This procedure makes a strong bond between metals, making it an important step in constructing durable components and structures. Different welding techniques include MIG welding or Metal Inert Gas welding, TIG welding or Tungsten inert Gas welding, laser welding or stick welding each suitable for various applications.

Welding plays a vital role in assuring the structural integrity of fabricated metal parts. It is widely utilized in sectors for example, automotive manufacturing, shipbuilding and pipeline construction. Since welding is an important factor of the fabrication procedure, it is usually used in combination with other metalworking techniques to achieve the desired outcomes.

The Role of Fabrication in Custom Metal Projects

Fabrication is considered as a comprehensive technique that begins with raw metal and transforms it into complete products. It includes different steps such as – designing, forming and assembling. Fabrication shops use advanced machinery, including CNC – Computer Numerical Control- cutters, laser cutting tools, and press brakes to shape metal with the right precision.

Custom fabrication is perfect for projects that need unique designs, intricate components or large-scale production. Whether it is making industrial machinery, structural frameworks or decorative metalworks, fabrication assures that metal parts are made to precise specifications.

Welding vs. Fabrication – which one is best suited for custom metal fabrication?

Both welding and fabrication are important for custom metal projects. However, their applications vary. The comparative study can look like:

1. Scope of the work

- Fabrication: Covers the complete procedure of cutting, shaping and assembling metal components to make a finished product.

- Welding: A particular technique used within fabrication to integrate metal parts, elevating structural strengths.

2. Application in custom projects

- Fabrication: Perfect for projects needing design modifications, cutting, custom-built components, and precisions.

- Welding: Best applicable for repairing, strengthening or joining metal parts that are already shaped and processed.

3. Material Compatibility

- Fabrication: Works with different raw materials, aluminum, including steel, stainless steel, and brass.

- Welding: Needs compatibility between metals to assure strong bonding, usually using specialized filler materials.

4. Project complexity

- Fabrication: Manages complex and multi-step projects that include structural frameworks, enclosures, and industrial equipment.

- Welding: Plays an important role in reinforcing as well as assembling fabricated structures to elevate strength and durability.

5. Precision & Customization

- Fabrication: Provides extreme levels of precision and customization with advanced forming and cutting techniques.

- Welding: Provides seamless joints as well as durability, making it important for load-bearing structures.

Selecting the Right Process for Your Custom Metal Fabrication Project

Selecting between fabrication and welding relies on the nature of the project. If your goal is to make a customized metal structure from scratch, fabrication will be the best selection. As it encompasses material selection, design and assembly, the choice will be best for custom needs. In case your project demands joining metal parts or reinforcing existing structures, welding will be the optimal technique.

For most of the custom metal fabrication projects, welding and fabrication go hand in hand. A professional metal fabrication company will join both techniques to ensure the extreme quality and durability of the final product.

Why Partner with an Expert Metal Fabrication Company?

When working on customized metal fabrication, you should seek for precision and expertise. Partnering with a skilled metal fabrication company assures:

- Access to advanced machinery and cutting-edge technology.

- High-quality materials and expert craftsmanship.

- Efficient project execution with attention to detail.

- Customization options tailored to specific project needs.

A trusted fabrication partner can manage both welding and fabrication seamlessly, allowing end-to-end solutions for businesses ranging from construction and aerospace to industrial manufacturing and automotives.

FAQs

- What is the difference between welding and fabrication? The entire process of making a metal structure, including cutting, shaping, and assembling, is called fabrication. A particular fabrication technique called welding uses pressure and heat to fuse metal components together.

- Can a metal fabrication project be completed without welding? The majority of metal fabrication tasks use welding as a vital process for assembling and reinforcing metal components, while certain projects might not.

- Which industries benefit from custom metal fabrication? Custom metal fabrication is advantageous to industries including construction, aerospace, automotive, shipbuilding, and industrial manufacture because of its accuracy and robustness.

- How do I choose the right metal fabrication company? Seek out a business with a solid reputation for providing top-notch bespoke metal fabrication services, a wealth of experience, cutting-edge machinery, and knowledgeable specialists.