The Ultimate Guide to Precision Metal Fabrication

Introduction

Turret punching, also known as punch pressing, is a popular method for creating precision holes in metal sheets. This process involves using a turret punch, which is a machine that punches holes in metal sheets with a high level of accuracy and speed. In this guide, we will explore everything you need to know about turret punching, from the basics of the process to the benefits of using this method for your metal fabrication needs.

What is Turret Punching?

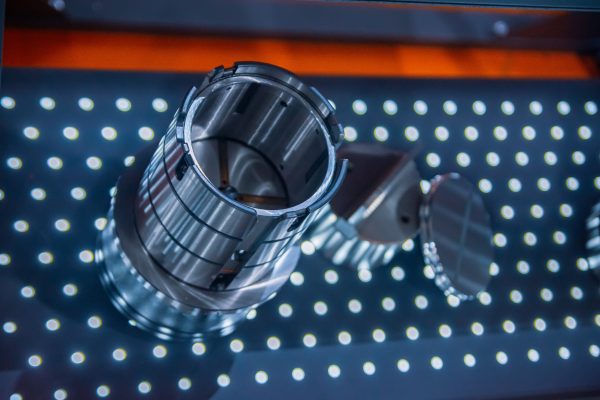

Turret punching is a metal fabrication process that involves using a turret punch to create holes in metal sheets. The turret punch is a machine that uses a punch and die to create holes in metal sheets. The punch is a cylindrical tool that is used to create the hole, while the die is a flat surface that supports the metal sheet and prevents it from deforming during the punching process. Turret punching is a highly precise process that is used in a variety of industries, including automotive, aerospace, and electronics.

Benefits

Turret punching offers a number of benefits over other metal fabrication methods. First and foremost, turret punching is a highly precise process that allows for the creation of holes with a high level of accuracy and consistency. This makes it an ideal method for creating complex shapes and patterns in metal sheets. Additionally, it is a fast and efficient process that can be automated, which can help reduce production time and costs.

How Turret Punching Works

Turret punching works by using a punch and die to create holes in metal sheets. The process begins with the metal sheet being loaded onto the turret punch. The punch and die are then aligned over the area where the hole is to be created. The punch is then lowered onto the metal sheet, creating a hole in the metal. The metal sheet is then moved to the next position, and the process is repeated. Turret punching can be used to create a variety of hole shapes and sizes, including round, square, and rectangular holes.

Applications

It is used in a variety of industries, including automotive, aerospace, and electronics. It is commonly used to create holes in metal sheets for the purpose of mounting components or attaching parts. It can also be used to create complex shapes and patterns in metal sheets, making it an ideal method for creating decorative pieces and other custom metal fabrication projects.

Conclusion

It is a highly precise and efficient method for creating holes in metal sheets. It offers a number of benefits over other metal fabrication methods, including speed, accuracy, and consistency. Whether you are in the automotive, aerospace, or electronics industry, it can help you create the precision holes you need for your metal fabrication projects.

For more information go to https://crescocustommetals.com/